13

2026

-

01

What Is a Thermoforming Packaging Machine? A Complete Guide for Global Buyers

author:

Definition of a Thermoforming Packaging Machine

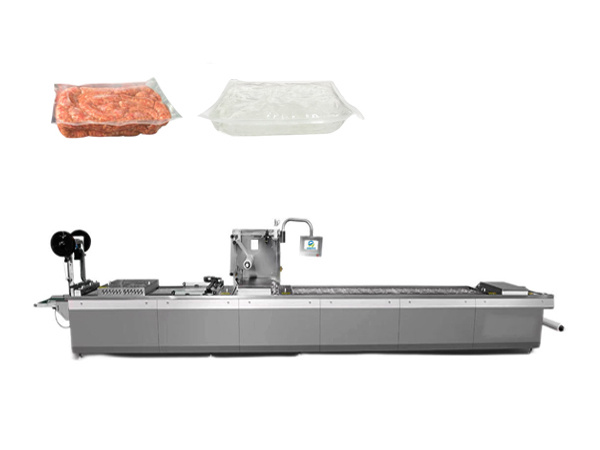

A thermoforming packaging machine is a fully automated packaging system that transforms flat plastic films or sheets into custom-shaped packages through heat, vacuum, pressure, or mechanical force, then completes sealing, cutting, and waste recycling in a continuous cycle. Internationally recognized as a core equipment in high-volume packaging lines, it integrates forming, filling, sealing, and trimming functions to produce vacuum-sealed, modified atmosphere (MAP), or skin packs for diverse industries.

Unlike traditional packaging machines, thermoforming equipment uses mold-based shaping to create tailored packages—from shallow food trays to deep medical blister packs—with high consistency and efficiency. It is widely favored in global markets for its versatility, automation, and ability to handle various thermoplastic materials like PVC, PET, PP, and aluminum films.

Core Working Principle & Components

Step-by-Step Working Process

- Film Feeding: Upper and lower plastic film rolls are fed into the machine with constant tension control to avoid wrinkles, ensuring flat sealing.

- Heating: The bottom film is heated to its pliable temperature (90–120°C for PVC, 120–160°C for PET/PP) via quartz or ceramic heaters, with uniform temperature distribution to prevent material thinning.

- Forming: The heated film is shaped into cavities using vacuum suction, compressed air pressure, or plug-assist technology. Molds determine the package’s size and shape, with cooling channels accelerating solidification.

- Filling: Products are loaded into formed cavities manually or via automated systems, with hygienic enclosures for food/medical applications.

- Sealing: The top film is laminated and sealed to the bottom film using heat and pressure. Medical applications comply with ISO 11607 standards to ensure sterility .

- Cutting & Waste Recycling: Finished packages are cut by horizontal/vertical blades, and waste film is automatically collected for environmental sustainability.

Key Components & Quality Standards

High-performance thermoforming machines rely on precision components, including:

- PLC Control System (e.g., Siemens S7-200T) for real-time parameter adjustment and fault diagnosis.

- Vacuum Pump (e.g., Busch, Rietschle) to achieve 0.1 mbar vacuum degree for optimal preservation.

- Pneumatic System (e.g., AIRTAC) for tight mold closure and stable forming.

- 304 Stainless Steel Frame for corrosion resistance and hygiene compliance.

Global buyers should prioritize machines complying with GB/T 24711-2009 (Chinese standard) and international norms, ensuring consistency in vacuum degree, sealing strength, and film cutting accuracy.

Types of Thermoforming Packaging Machines

Machines are classified by automation, output, and application to meet diverse production needs:

|

Type |

Key Features |

Speed |

Ideal Applications |

|---|---|---|---|

|

Manual |

Operator-controlled, low cost, flexible for prototypes |

1–3 cycles/min |

Small-batch production, custom samples |

|

Semi-Automatic |

Automated heating/forming, manual loading |

3–5 cycles/min |

Medium-scale food/electronic packaging |

|

Fully Automatic |

Integrated workflow, mold customization |

4–12 cycles/min |

Mass production (meat, seafood, medical supplies) |

|

Pressure-Forming |

Dual pressure/vacuum for fine details |

5–8 cycles/min |

Premium packaging with embossed logos |

Industry Applications

Thermoforming machines serve across sectors with tailored solutions:

- Food Industry: Vacuum packaging for meat, seafood, and ready meals; MAP for bakery products to extend shelf life.

- Medical Industry: Sterile blister packs for syringes, masks, and surgical tools, complying with strict hygiene standards.

- Electronics: Anti-static, moisture-proof packs for precision components.

- Consumer Goods: Clamshell packs for cosmetics, hardware, and pet food.

How to Choose the Right Machine for Your Business

Key Selection Criteria

- Production Volume: High-output machines (8–12 cycles/min) suit large factories, while compact models fit small-scale operations.

- Product Specifications: Thermoforming depth determines package size—choose deep-draw models for bulky products.

- Material Compatibility: Ensure the machine handles your film type (flexible/hard/aluminum).

- Compliance: Prioritize ISO, GB/T 24711-2009, and industry-specific certifications (e.g., FDA for food).

- After-Sales Support: Select suppliers offering spare parts, on-site maintenance, and technical training for global operations.

FAQ (Frequently Asked Questions)

Q1: What’s the difference between vacuum forming and pressure forming?

A1: Vacuum forming uses suction to shape film, ideal for low-cost, high-volume trays. Pressure forming adds compressed air (up to 100 psi) for sharp edges and detailed textures, suited for premium packaging <superscript:3.

Q2: How long does it take to recover the machine investment?

A2: Full automation reduces labor costs—ROI is typically 6 months to 2 years, depending on production volume <superscript:4.

Q3: Can one machine handle multiple package sizes?

A3: Yes—removable molds allow quick changes (5–10 minutes) to adapt to different product dimensions <superscript:2superscript:8.

Q4: What maintenance is required?

A4: Regular checks of vacuum pumps, heaters, and blades; lubrication of moving parts; and calibration of temperature sensors to ensure performance <superscript:7.

Q5: Are thermoforming machines environmentally friendly?

A5: Yes—waste film recycling systems minimize material waste, and energy-efficient heaters reduce power consumption <superscript:2superscript:8.

Conclusion

Thermoforming packaging machines are indispensable for modern manufacturing, offering flexibility, efficiency, and compliance with global standards. By understanding their working principle, types, and selection criteria, global buyers can invest in equipment that aligns with production goals and industry regulations. For customized solutions or technical support, connect with certified suppliers specializing in international markets.

thermoforming packaging machine,thermoforming machine for food packaging,modified atmosphere packaging machine